Engineering Components Business

We develop safety-critical and high-performance components for both domestic and international markets.

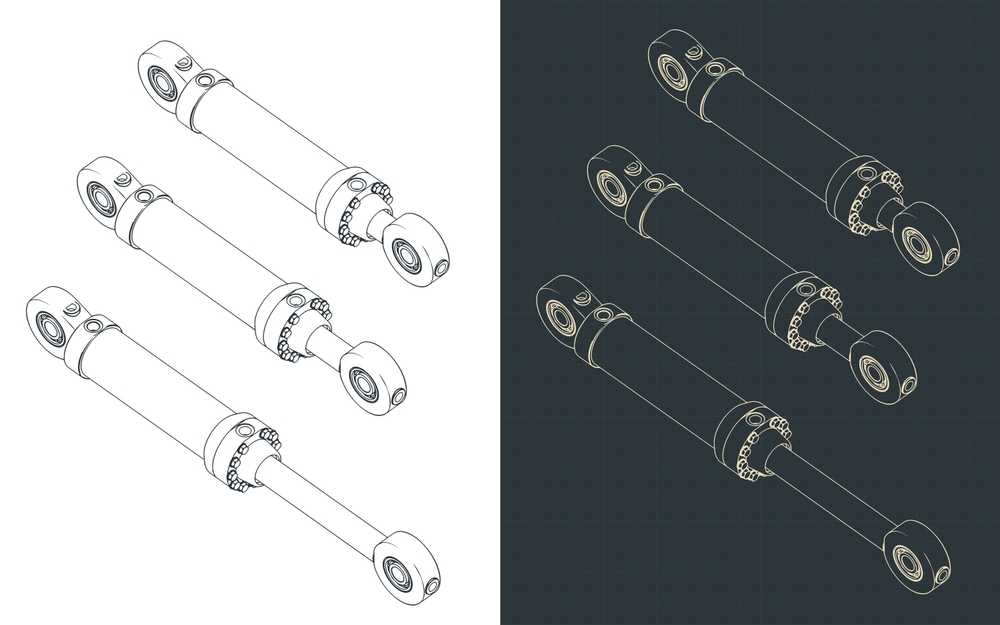

With in-house prototyping and development capabilities, we partner with customers to create customized products for hydraulics, industrial components, PSA and white goods segments.

Our state-of-the-art manufacturing plant, spread over 40 acres, is located on the outskirts of Chennai. A 1,000+professional army works diligently here to produce top-notch engineered products.

Manufacturing Capabilities

- Over a decade of experience

- Capability to serve customized solutions

- Ability to conceptualize, design, engineer and manufacture

- Complete control and access to raw materials

- Quality and consistent supply of products

- Global products with world-class quality

- Proven track record to global customer We pride in being perennially agile, adaptive and advanced. Over the years, we have progressively progressed to producing higher value-added components, entailing investments in higher capital equipment and building our technical competencies

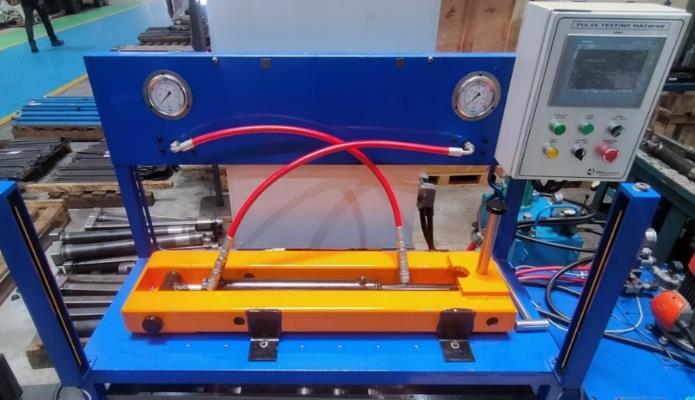

STATE-OF-THE-ART VALIDATION LAB TO VALIDATE OUR CREDENTIALS! Start-of-the-art validation lab to validate our credentials!

- Pressure testing

- Burst test equipment

- Pulse test rig

- Back-to-back endurance test rig

- Load test equipmen

We manufacture high-precision components for construction equipment and off-highway vehicles, including loader arms, dippers, booms, buckets, and sub frame/support arms. The state-of-the-art facilities are equipped with advanced equipment viz., Boschert Precicut Plasma turret punch machine, high tonnage Durma press brake, robotic welding, shot blasting, and painting capabilities. They allow us to efficiently produce small to large components on time

- Shearing Machine & Laser cutting machine

- CNC Turret punching with plasma cutting machine

- CNC press brake bending

- Pulse machine welding

- Short blasting machine

- Spray paint booth

- Laser Welding M/c

- Robotic Welding M/c

Automotive Components We manufacture critical automotive components including brake and suspension systems, auto electricals, and structural assemblies. We have the competence and capability to handle high volume production. Our product development cell is equipped to address customer-specific requirements and develop custom solutions

White goods We have vast experience and expertise in handling critical, customized components for white goods applications and are pioneers in deep-drawn components. Our first-rate plant at Patancheru meets and even surpasses global standards