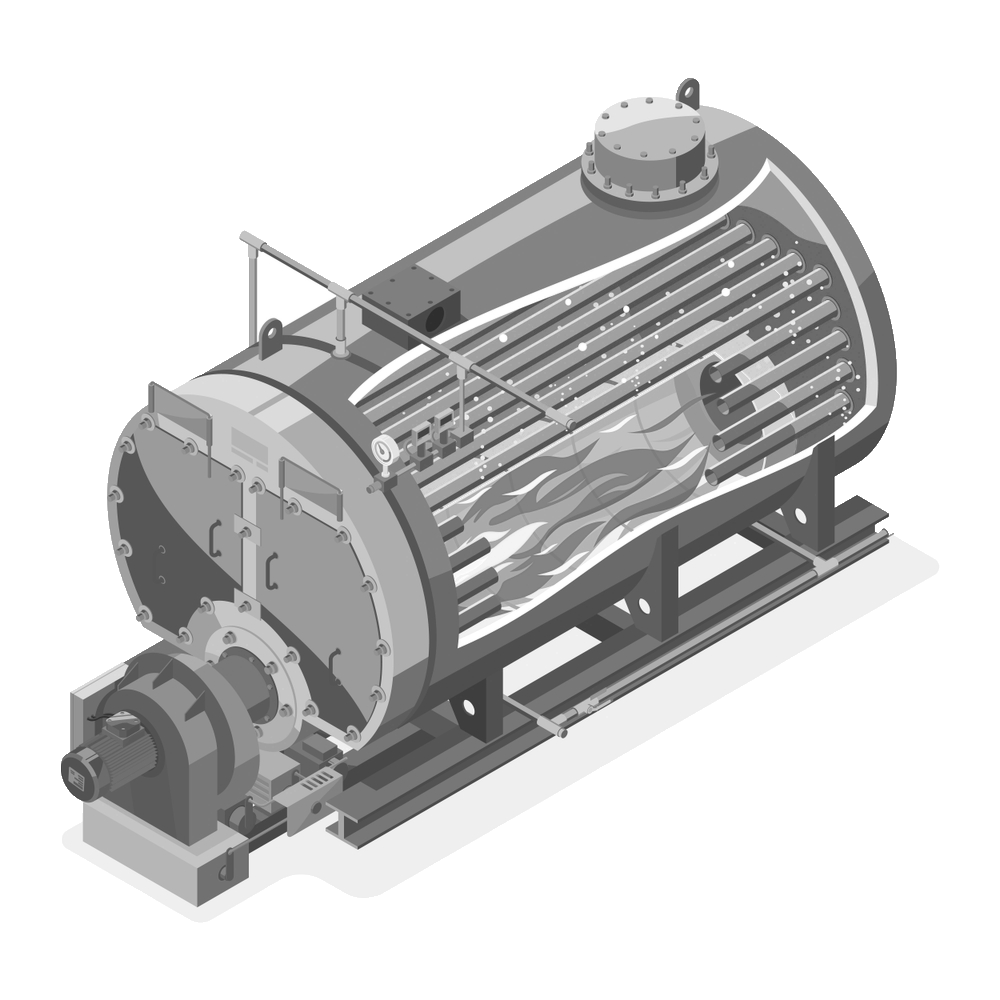

BI-DRUM BOILER

The reliable Bi-Drum Water Tube Boiler for Process & Co-Generation

Pennar Industries Boiler Business Unit offers specially designed water tube boilers for large capacity process steam application and Co- generation Systems for process Industries to cater to their process steam as well as their Power requirements.

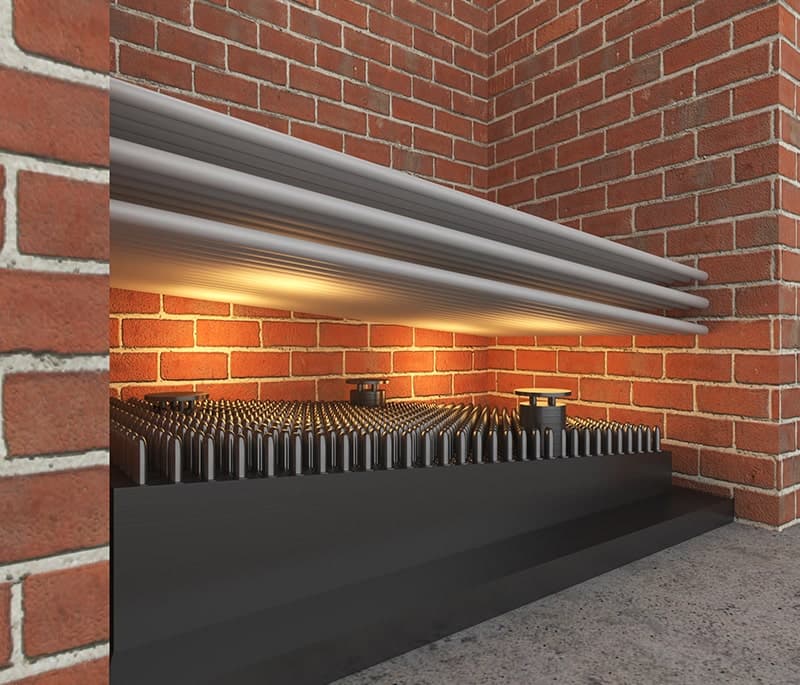

The system consists of a classical water tube boiler in Bi-Drum construction designed to burn a variety of biomass fuels like Paddy Husk, Saw Dust, GN shells etc as well as both Indian and Imported Coal in a Fluidized Bed Combustor.

Other combustor options like Traveling Grate, Reciprocating Grate and Dumping Grate can also be offered based on fuel combinations. Selected Combustion System ensures complete combustion of fuels in a turbulent furnace thereby resulting in highest efficiency.

Superheater is provided to deliver superheated steam which is fed to a steam turbine for power generation. Back pressure steam from the turbine is used in the process for heating applications.

The flue gases coming out of the boiler passes through downstream heat recovery systems like Economizer and Air Pre-Heater to further extract the residual heat from the flue gases before being sent to Pollution control devices like Bag Filters/ESP.

The Boiler operations can be fully automated with sophisticated PLC controls and SCADA systems.

Range:

- Capacity: up to 50 Tons/Hr

- Pressure: up to 67 Kg/cm2(g)

- Superheat Temperature: up to 490°C