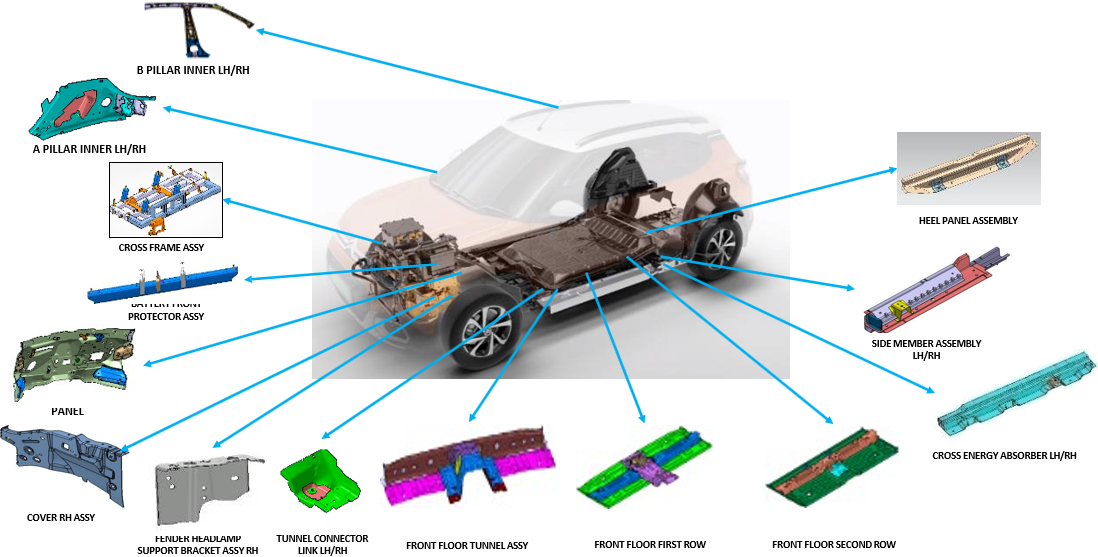

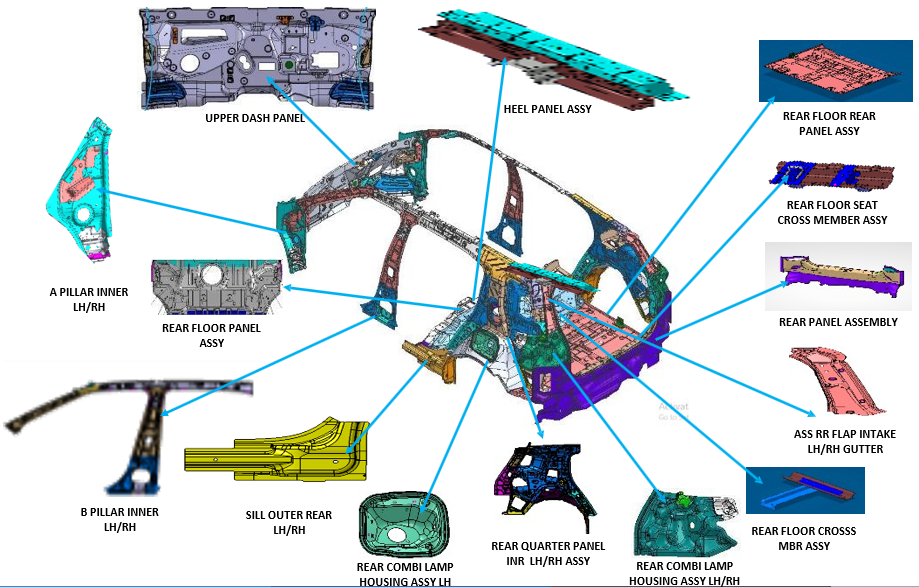

The importance of the BIW lies in its role as the backbone of the vehicle. It provides the necessary strength, stiffness, and durability to ensure the vehicle's overall structural integrity. Therefore, it is no surprise that a well-designed and well-constructed BIW is crucial for a safe and reliable vehicle.

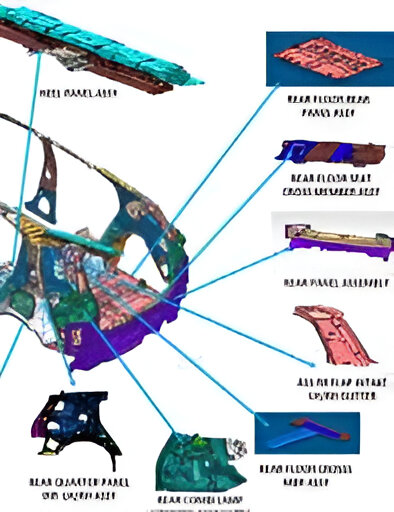

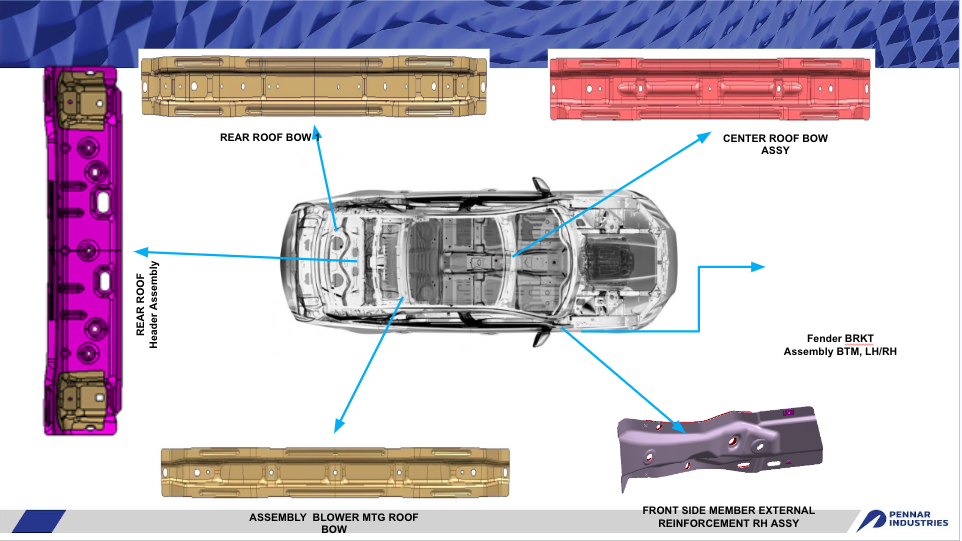

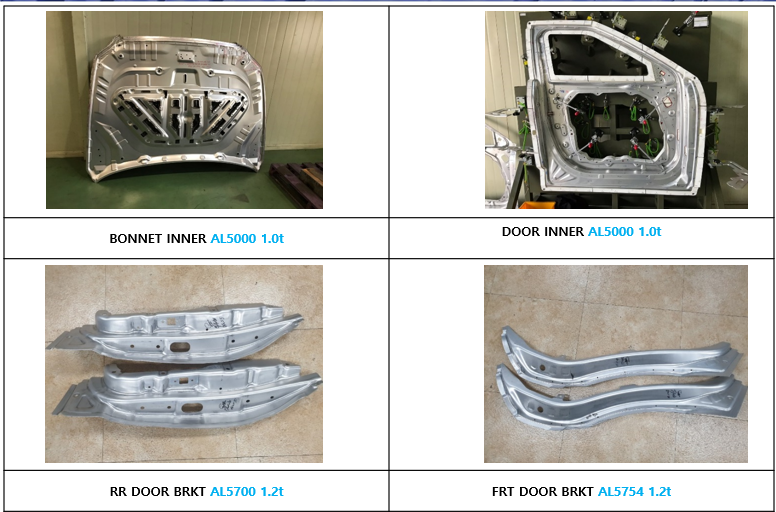

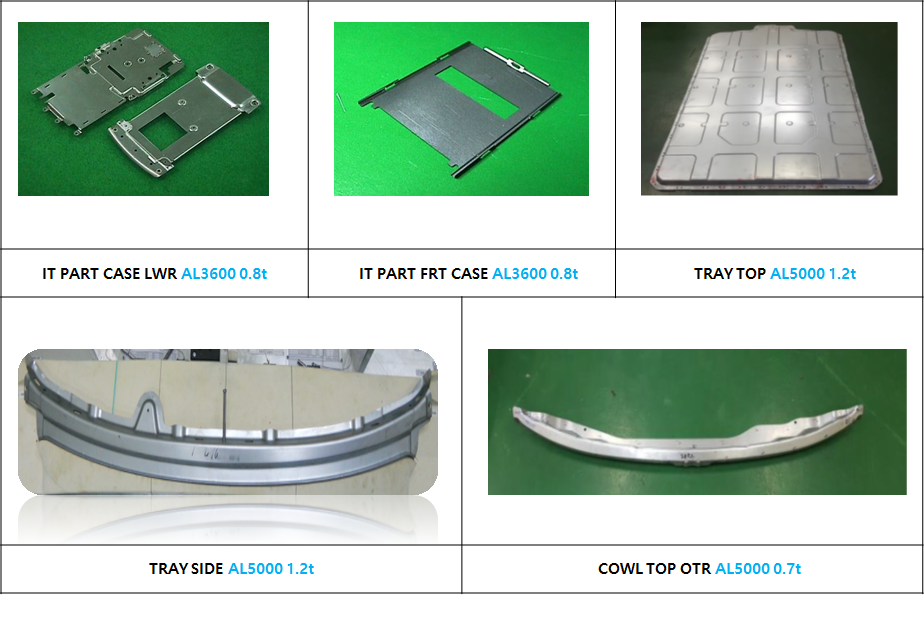

Pennar provide major sub-assemblies for BIW construction which includes Roof, Quarter panels, Floor pan, Bulkheads, Floor cross members, A-pillars and B-pillars, all of which contribute, to a greater or lesser extent, to the stiffness of the vehicle.

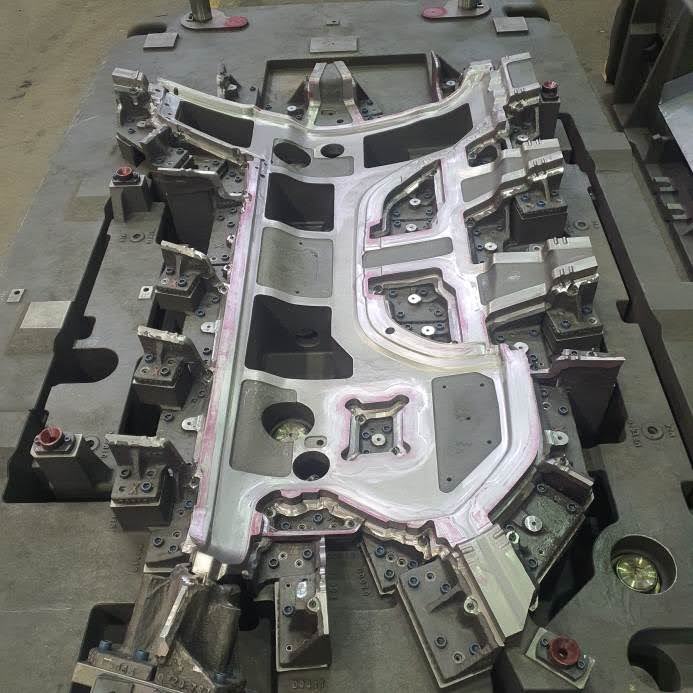

Pennar has a large portfolio of technologies, which allow working in different formats and materials. Productive processes that cover the entire value chain. From the internal capacity of manufacturing of Dies, to finishing technologies, and a wide range of forming technologies, as well as welding and assembly

Pennar is the largest global supplier of hot stamping parts. Our press hardening production model cover the entire value chain from the manufacturing of our own dies to production lines

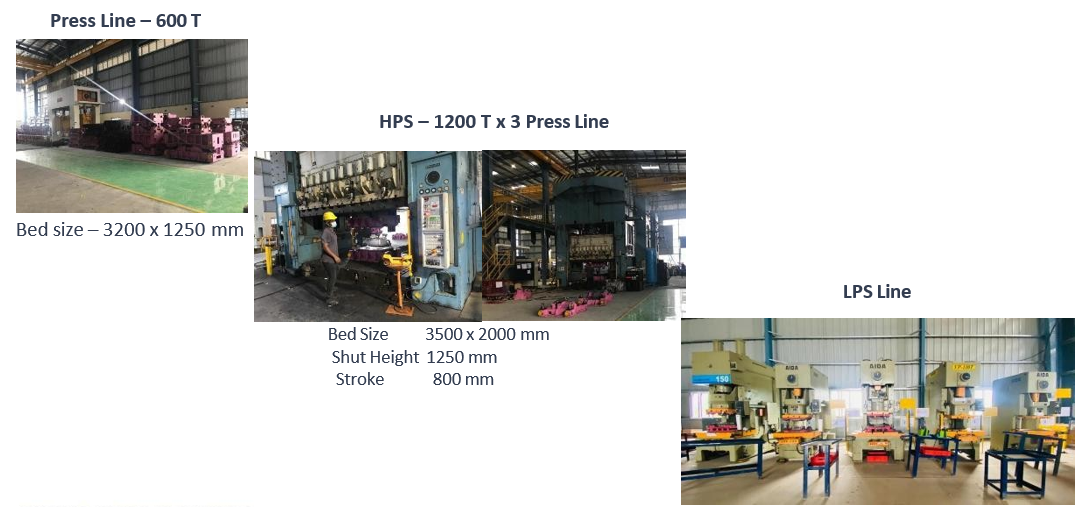

Cold forming allows us to manufacture a range of parts from small reinforcement parts to a complete car body side. We operate presses in the upper range of forces of greater than 1,000 tons and consequently we can stamp high strength materials. Ultra high strength steels are an important part of weight reduction solutions for the car body structure

As a result of greater demand for collision impact response and weight reduction in the structural components of the body, there is a growing use of high strength steels. Pennar experience in manufacturing processes and in the internal manufacturing of dies to work with HSS/UHSS materials is a guarantee of our product’s quality.

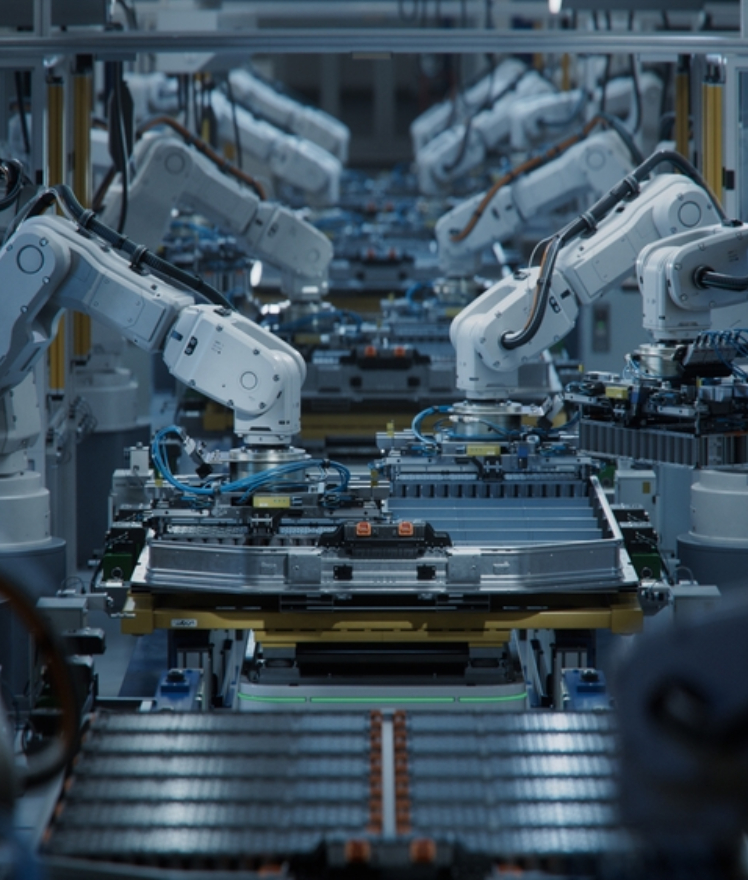

Pennar body shops use the most advanced technologies for assembling complex. We use parts resistant or spot welding in the welding of Ultra High Strength Steels. Our welding cells are typically highly automated, and we use automated robots to perform several of the most precise operations inside the welding cells to achieve maximum cost reduction and ensure we produce the highest quality assemblies.

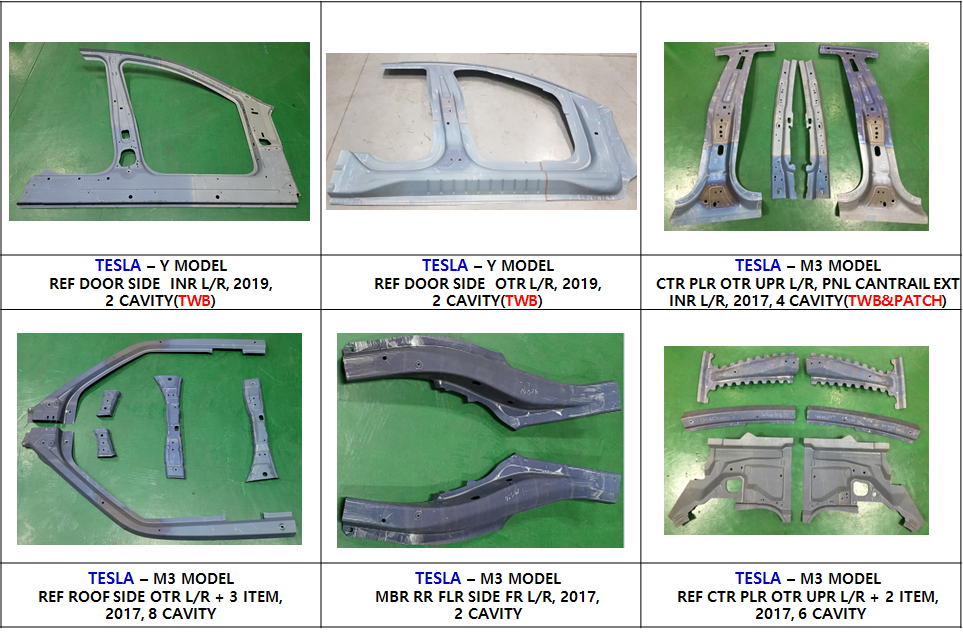

Pennar has Comprehensive range of services and strategic partnership across the world in hot stamping, light weighting technologies like aluminium and high strength steel amongst others

End-to-end solutions provider for all business segments including passenger vehicles, commercial vehicles and Off Highway vehicles.

Pennar Industries currently supplies to one of the largest car makers in the world – STELLANTIS & TI-Group