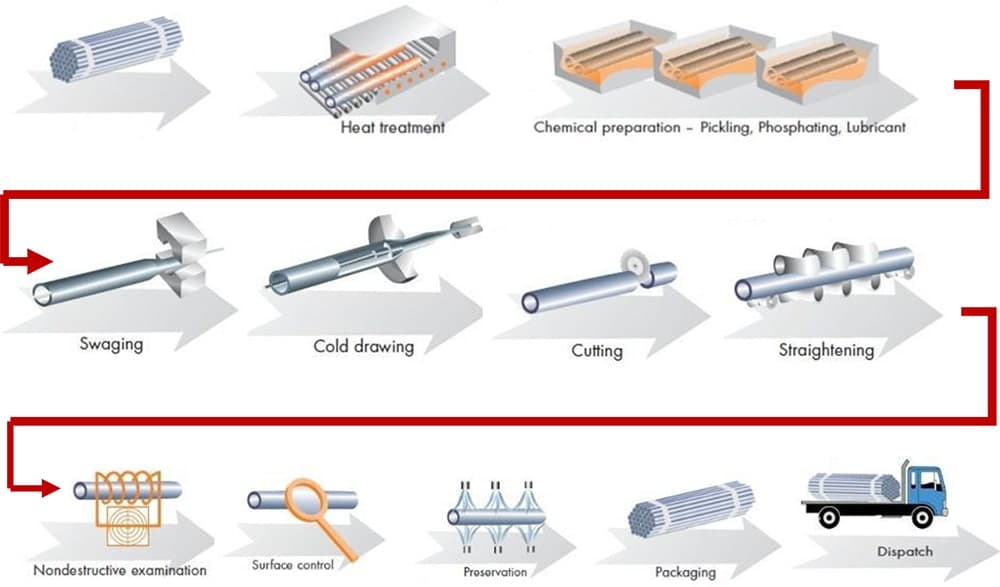

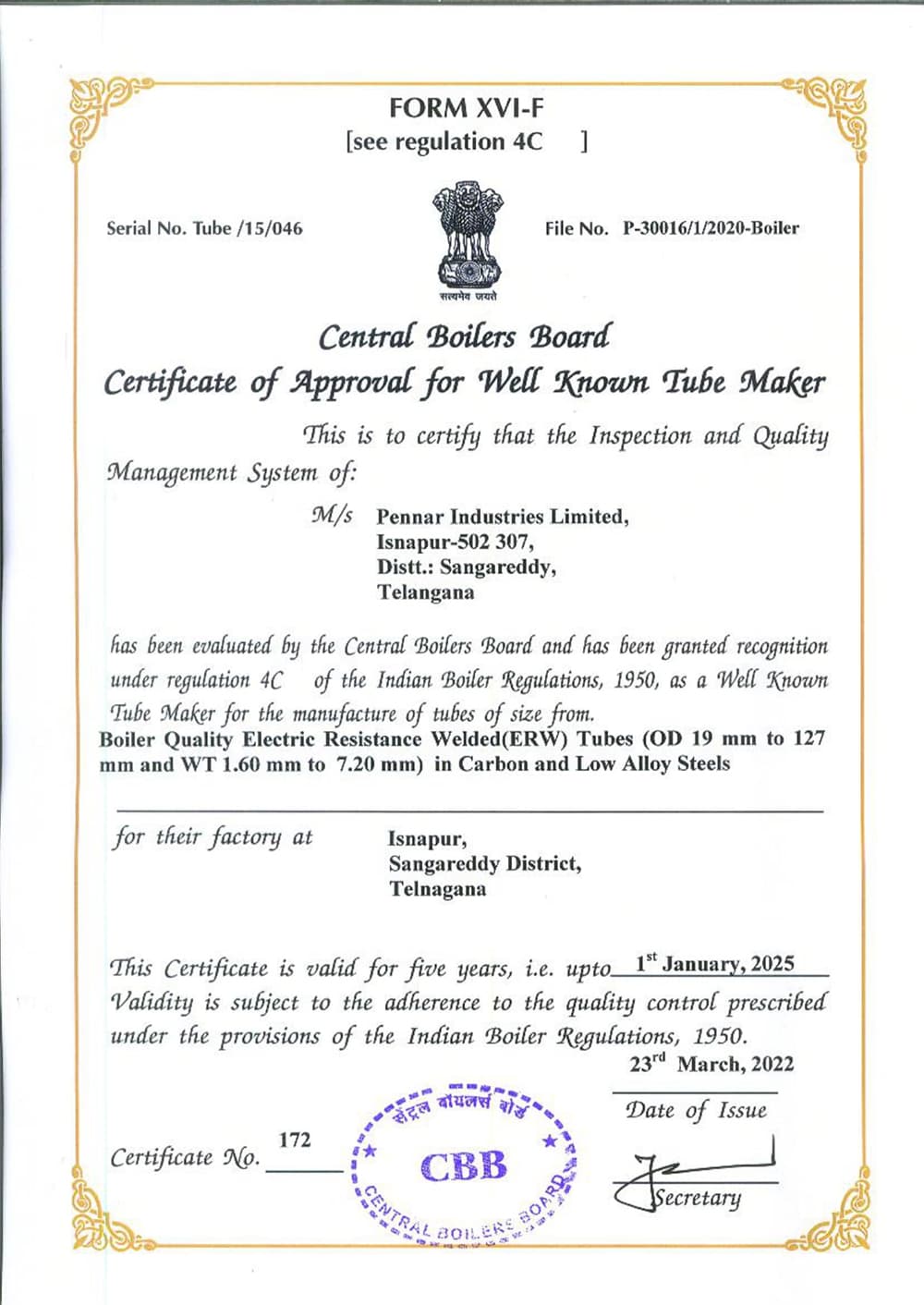

Why are our ERW tubes exceptional in quality?

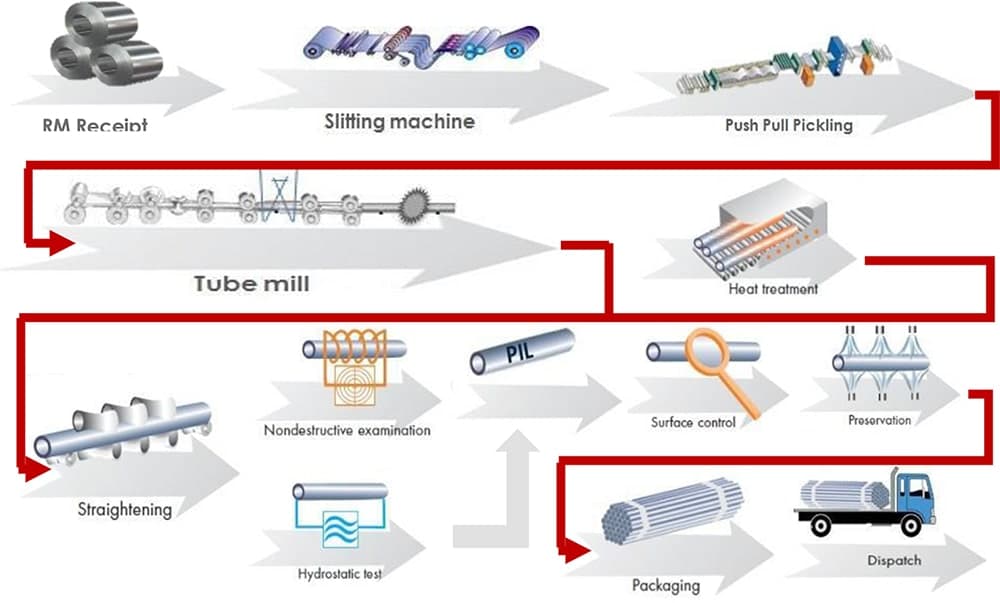

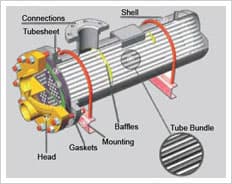

Pennar Industries is the go-to name when it comes to ERW Tubes. Pennar Industries produces high-quality tubes conforming to IS 3074 and IS 4923 standards. Our in-house tooling capability helps in producing specially designed rolls for the progressive movement of steel strips. This reduces costs as well as delivery time.

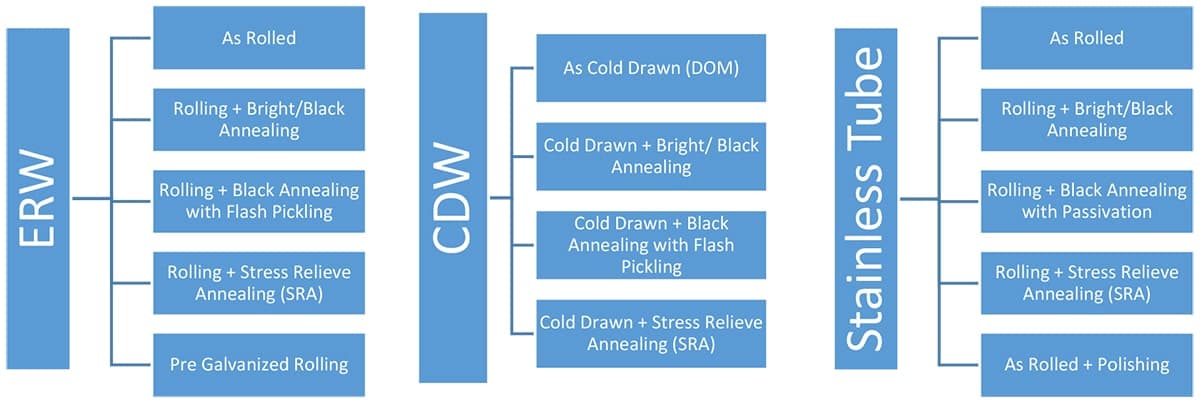

- High frequency induction welding process without any filler material for welding of butted ends.

- Deburring units remove the internal and external hot weld flash for smooth finish.

- Turks head and sizing roll ensure straightening & sizing of tubes into various sections such as rectangular, square, elliptical and oval.

- Annealing, Pressure testing, Eddy current testing, straightening or cutting ensure quality and fitness for required application.

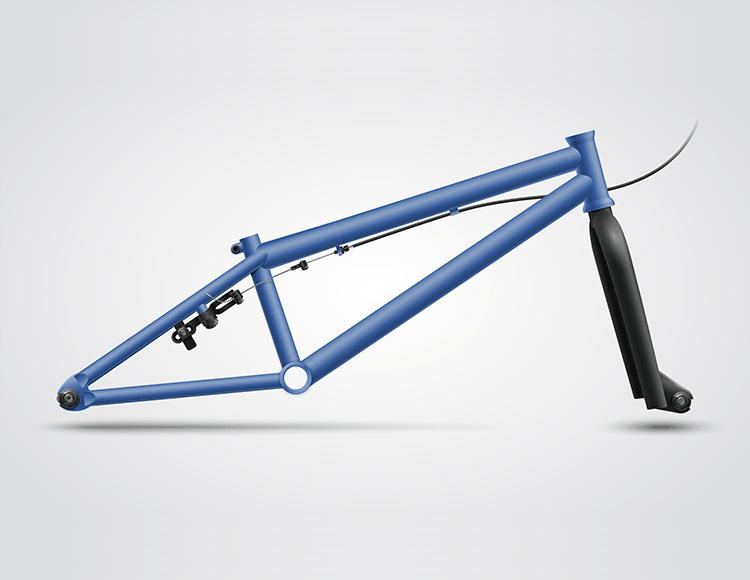

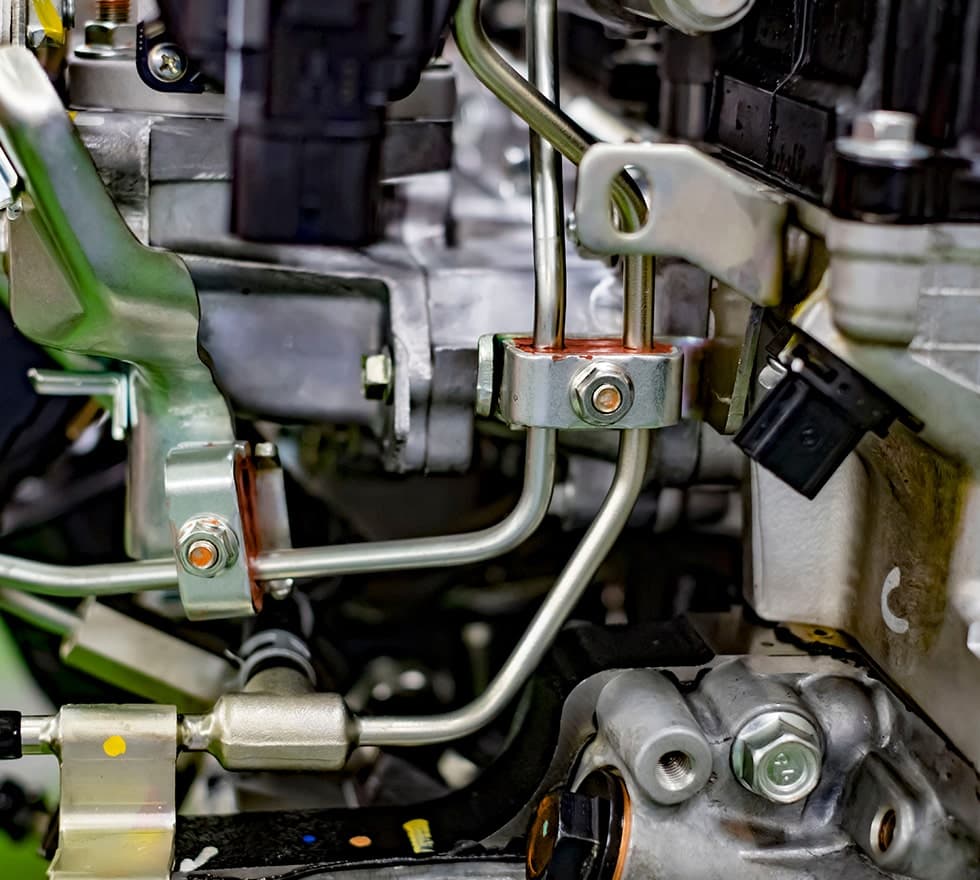

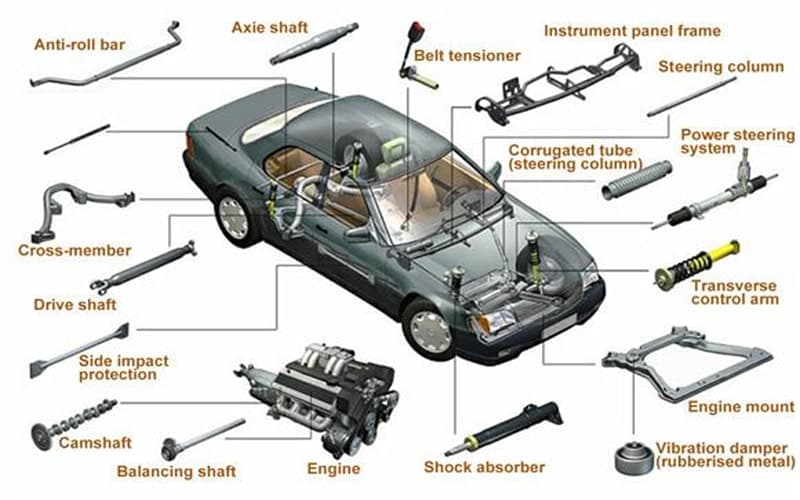

Automobiles

- Load Body Tubes

- Bus body Tubes

- Seat Frames

- Earth Moving Equipment ROPS

- Automobile door impact beams

Others

- Structural Tubes

- Solar Structures

- Agriculture Equipment

General Engineering

- Furniture Tubes

- Bearings and spindles, Trolley handles

- Hydraulic and pneumatic line, Electrical conduit

- Oxygen lancing pipes, Cycle pumps

- Industrial chain roller, Gas stove lighters

- Electrostatic precipitators

- Textile frames and Bobbins

- Main beam for pedestal fans

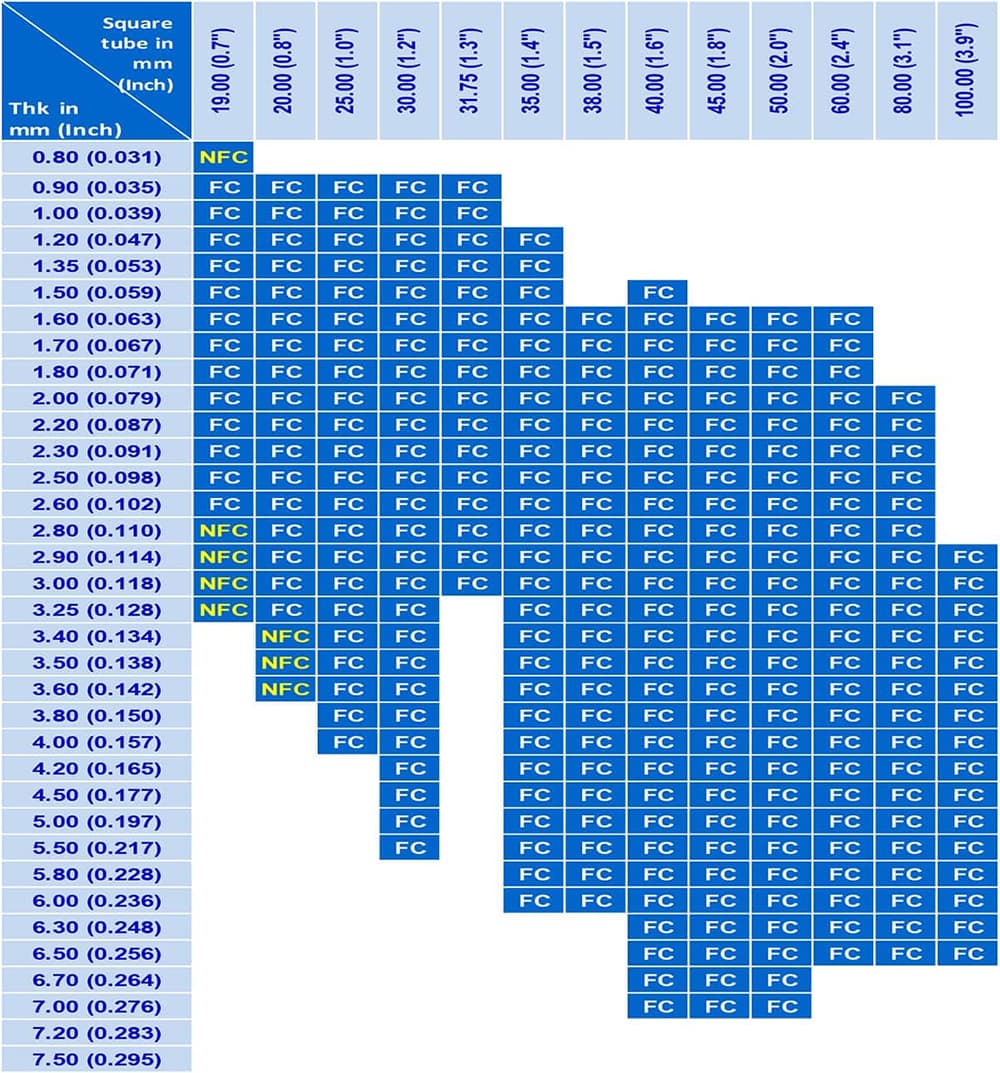

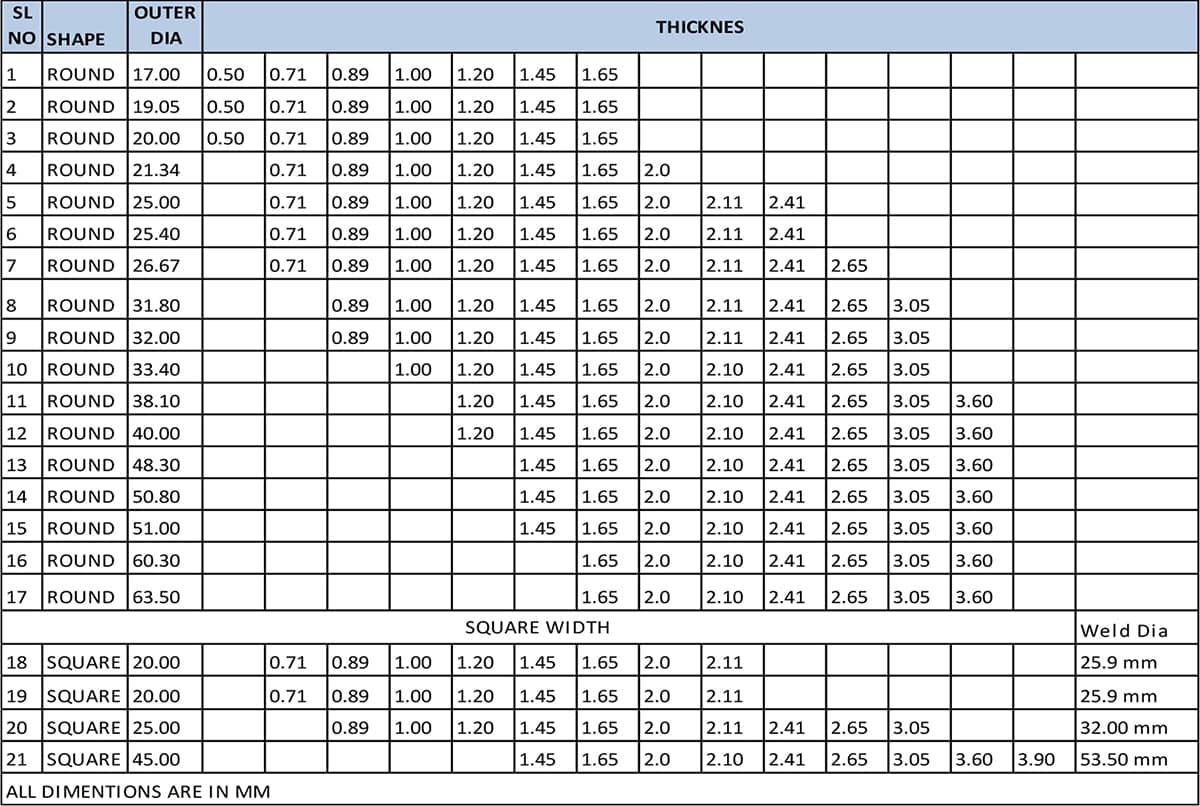

ERW (Square) Tube Capacity Chart

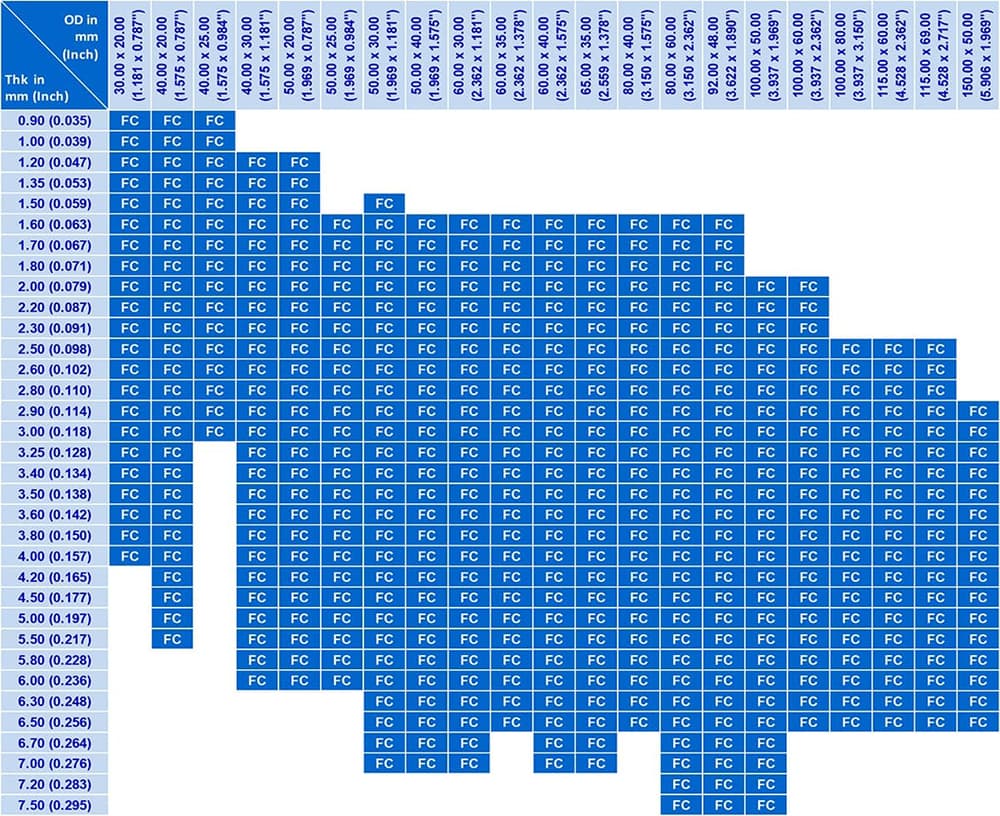

ERW (Rectangle) Tube Capacity Chart

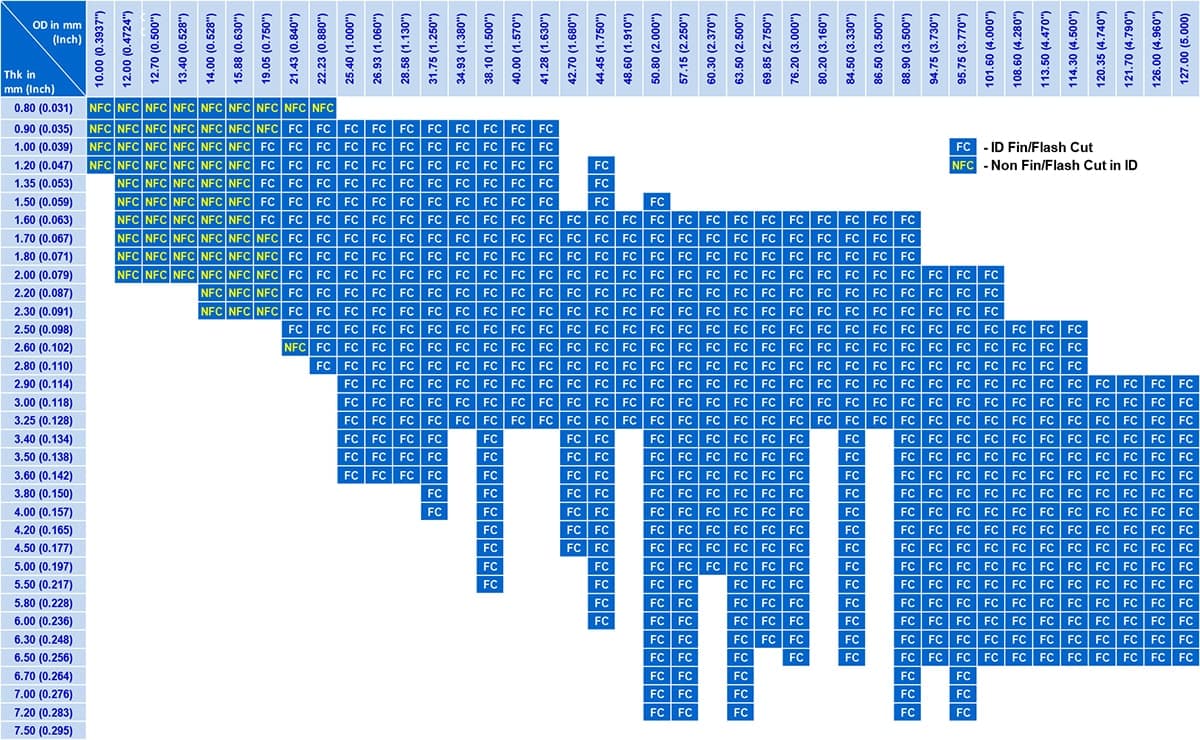

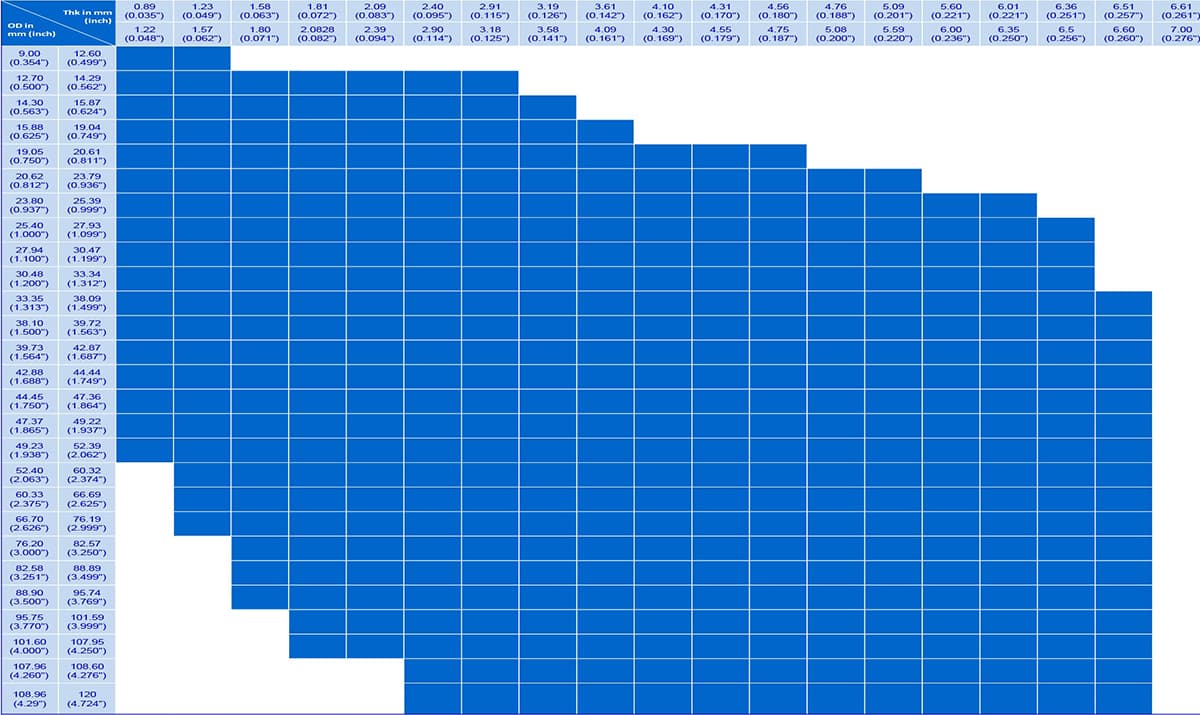

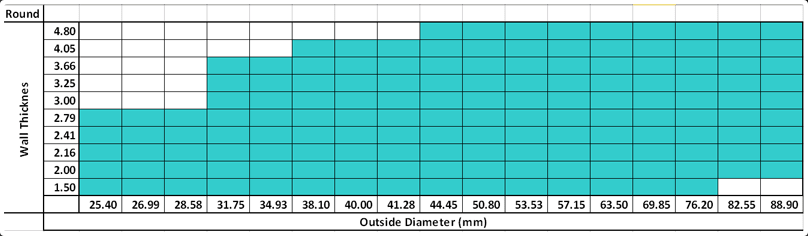

ERW (Round) Tube Capacity Chart

.jpg)