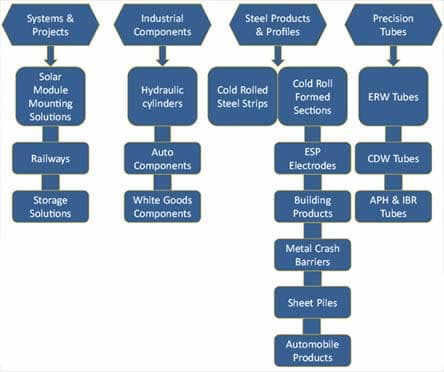

Pennar Industries caters to a wide variety of industries that include Automobile, Infrastructure, Railways, FMCG, Warehousing, Power, Logistics, etc.

Pennar Industries has a huge client base of more than 500 which include the leading companies in India like Eicher, Alstom, Ashok Leyland, Bajaj, Thermax, F L Smidth, Godrej, Integral Coach Factory, BHEL, BEML, Nagarjuna Constructions, L&T, Lanco, Tata motors etc. to name a few.

Pennar Industries has a combined capacity of manufacturing 350,000 MT per annum.

We have a pan-India presence with eight manufacturing facilities situated across the country. These facilities include laser cutting, plasma cutting, transfer presses and CNC machines that enable it to make products of very high quality. All the plants are ISO certified. Pennar Industries endeavours to achieve ‘total customer satisfaction through total quality management’ and is committed to produce and provide steel-based products and associated services of the highest quality to customers all over the world.

CRSS (Cold Rolled Steel Strips):

Cold rolling is the process of thickness reduction of Hot Rolled Steel. In the process of this thickness reduction, there is value addition done to the product by having processes like pickling and annealing in the process.

CRFS (Cold Roll Formed Sections):

The cold roll formed sections are all the products that are formed from steel strips (either cold rolled or hot rolled)

Fabrication:

The processes that are involved are TIG welding, MIG welding, Arc welding and resistance welding

ICD:

The ICD division uses machines like hydraulic and mechanical presses and punching machines, to draw components from metal sheets.

Tool Room processes:

Tool room has a state of the art CNC machines along with design capabilities for addressing the tooling needs.

We have ISO 9001:2008, ISO/TS 16949:2008 Quality certified company

- Anaar, 5S, TPM, and QFD will bring about change in

- Facts measurements

- Process Improvements

- Process leaders allocation

- Process Performance Benchmark

- Periodic review of the processes for continuous improvement

We aim to achieve TPM by increasing employee participation and maximizing equipment efficiency by embracing the 8 TPM Pillars: Individual Improvement, Autonomous Maintenance, Planned Maintenance, Quality Maintenance, Education and Training, Development Management, Safety Health and Environment and Office TPM

We are dedicated to make Pennar Industries a safe working environment for all its employees. We have taken up a lot of initiatives for improve the overall HSE culture in the company.

We have started the process of acquiring OSHAS and IS 14001 certifications