Process Heating – Pennar Veesons Boilers

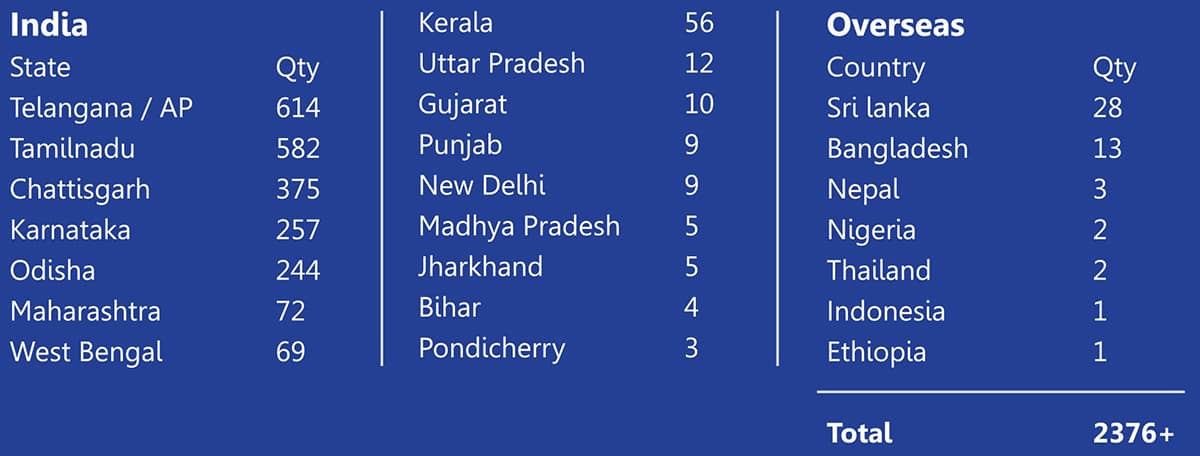

Turbosteam Boiler has been designed specifically for the Rice Mill Industry. Over 2000 boilers working successfully, both in India and overseas are a testimony to the quality and reliability of our product design and manufacturing.

Husk is conveyed pneumatically from the bunker to the boiler furnace through a fuel feeding nozzle and a spreading cone arrangement.

The furnace is provided with a specially designed Bubbling Bed Combustor for suspension burning of the fuel. Complete combustion of the fuel Is achieved with minimum unburnt loss, resulting in high thermal efficiency of the boiler.

"Pennar has acquired the Veesons brand as well as the design and technology of Veesons boilers" from the promoters of Veesons. Veesons have supplied more than 5100+ boilers over the last three decades and these have been running successfully both in India and overseas across a diverse spectrum of industries. Customers can continue to expect the same high level of reliability, quality and performance of boilers that have been the hallmark of Veesons!

This boiler has a multi fuel capability. We can burn other fuel like Wood and GN Shells on a stationary grate by providing specially designed grate bars in the furnace.

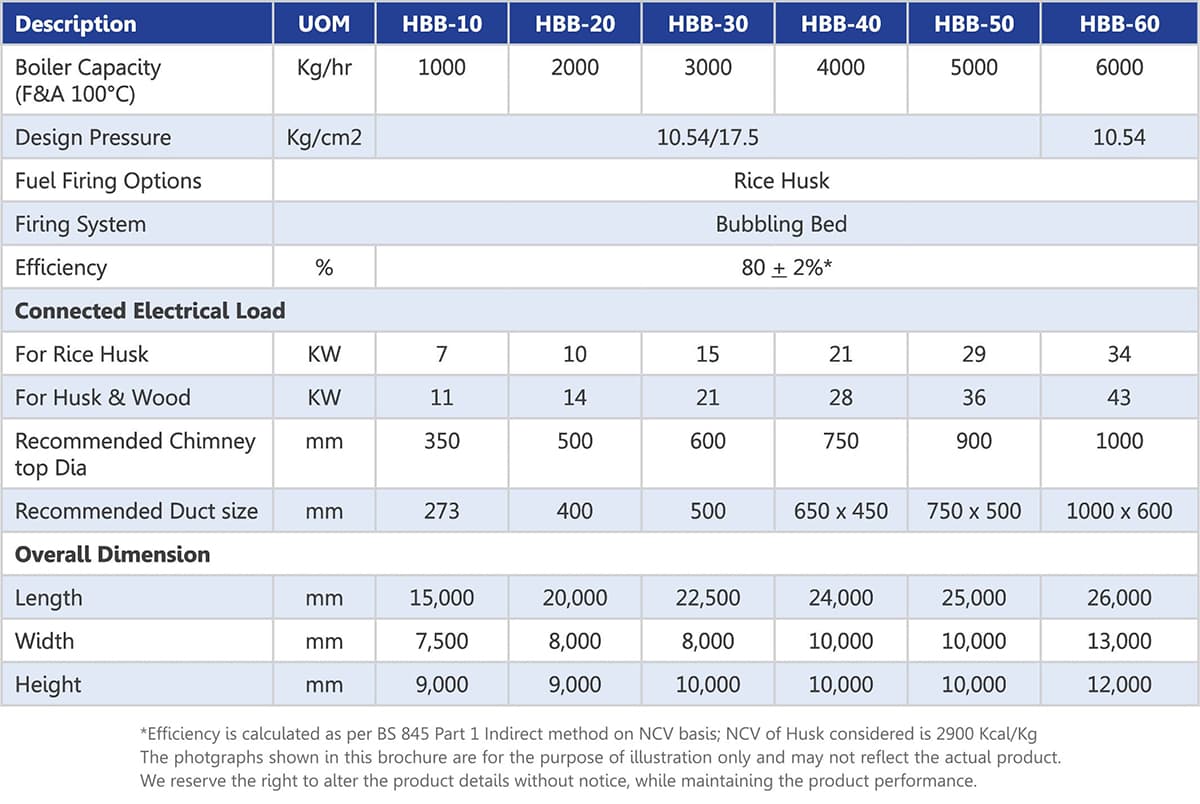

Range:

Capacity : 1.0 to 6.0 TPH

Pressure : 10.54 / 17.50 Kg/Cm2 (g)

Three Pass Integral Furnace Shell Type Boiler

Compact Foot Print

Specially Designed Honeycomb Wall Enable Heat to Attain Higher Residence Time

Multi Fuel Capability

Innovative Design of Secondary and Tertiary Combustion of Fuel

Highly Efficient and Fully Automatic

Quality Components like Forged Steel Valve

Single Fan Design Ensures Reduced Power Consumption and Operation Ease

Thorough Fuel and Air Mixing Ensures Minimum Unburnt loss

Quick Response to Fluctuating Steam Demand

Minimum Site Work and Very Low Refractory